|

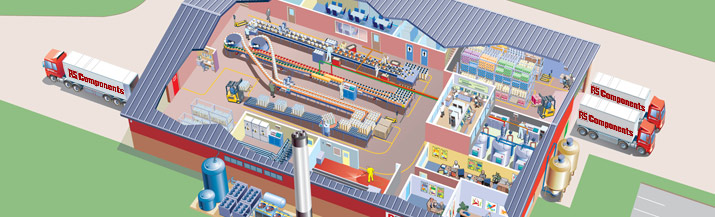

Building Maintenance

Workshop

Latest products for Plant Maintenance applications

We are constantly expanding our offer with the latest solutions from the leading industrial brands

Related articles in DesignSpark

Understanding safety components for machine guarding

Working safely in high places

Predictive maintenance within production lines

Times running out for NiCd Power Tool Batteries

Creating customised labels within a minute

Effective protection under extreme conditions

Building Maintenance - Finding Electrical Problems Faster

Within building maintenance, identifying electrical issues within panels, cabinets or equipment, can take time and present a safety hazard, while also being in hard to reach places. Reducing downtime and locating the source of the problem, safely and quickly can be achieved using thermal imaging.

Flir's All-in-one Thermal Imager and Clamp Meter (CM174) is the first clamp meter with a built-in thermal imager that can guide you to the precise location of an electrical problem area safely, which can then be confirmed with accurate amperage and voltage measurements.

Production Line - Predictive Maintenance

With any production line it is essential that the system is maintained, to avoid equipment failure and costly down-time. Predictive maintenance can help avoid these issues, by having a planned schedule that determines the most cost-effective manner for the maintenance to be carried out before the equipment loses performance or fails, which also has benefits of increased plant safety, fewer down times and optimized spare parts handling. Predicting failure can be carried out by integrating sensors into existing systems or equipment, such as vibration, where a sensor is placed on machinery such as on motors, gearboxes, pumps and fans, and then any vibration above a pre-set limit triggers an alarm condition.

Workshop - Creating Customised Labels Within a Minute

Clear and durable identification of infrastructure equipment directly affects productivity and safety in a profound manner. Labels are used for a wide variety of applications in a facility and provide an easy and legible way for workers to identify items quickly. For general identification needs – like labelling bins and beams, drawers or other items - a standard, industrial strength label can be used. For other labelling applications more specific types of labels are required.

With DYMO XTL you can simplify labelling by creating customised labels fast using the PC connectivity and free software, or simply use the built-in templates to make label creation simple and easy.