|

What is a DIP switch?

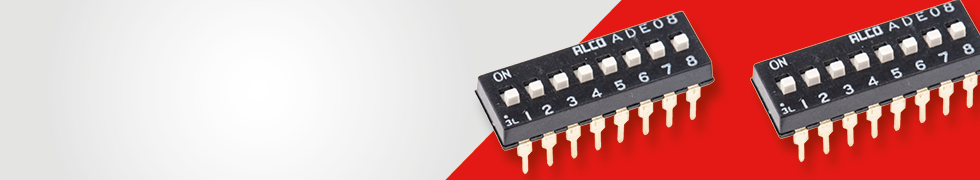

In electronics, the acronym DIP when applied to switch types stands for ‘dual in-line package’. A dual in-line package switch, or DIP switch, is actually set of small manual electronic switches that are designed to be packaged with other circuits. The term DIP switch may refer either to an individual switch on a multi-switch unit, or to the entire unit as a whole.

In a nutshell, the role of DIP switches is to allow users to control the flow of electricity around a printed circuit board (PCB), expansion card or other electronics/computer peripheral, and therefore change the operating mode of a device.

When installed on a PCB alongside other electrical components, DIP switches offer the potential for the user to customise the behavior of the electronic device in question, enabling fuller control over the precise function the device will perform in a range of defined scenarios or applications. DIP switches are typically presented as a row of tiny toggle (on/off) switches, rather like a series of miniature standard light switches, mounted sequentially on a block of heat-resistant thermoplastic polymer.

As a complete component, a set of DIP switches is almost always very small, requiring some dexterity on the user’s part to toggle each switch between on and off positions. In day to day practice, this function is often performed with the point of a sharp pencil or a similar suitably shaped tool, as the individual switches themselves tend to be too small for comfortable finger operation. A DIP switch is a relatively simple and cost-effective component that’s commonly used as an inexpensive way to select and change between various hardware or device options. They’re usually considerably cheaper than other options such as software control panels or programmable chips, with the compromise being that DIP switches require the user to physically open the device to access the PCB, and operate the switches manually from there.

A DIP switch is a relatively simple and cost-effective component that’s commonly used as an inexpensive way to select and change between various hardware or device options. They’re usually considerably cheaper than other options such as software control panels or programmable chips, with the compromise being that DIP switches require the user to physically open the device to access the PCB, and operate the switches manually from there.

In this guide, we’ll look more closely at what the precise form and function of a typical DIP switch set usually entails, as well as assessing the numerous types available on the UK market, and the various sorts of applications or devices they’re commonly bought and used in.

DIP switch uses

DIP switches are less widely used today than they once were, due largely to the trend for downscaling and the falling costs for other comparable solutions (for example selecting device output options through built-in software control). However, they’re still fairly commonplace in a wide range of industrial applications and test circuits.

This is because manual DIP switches offer an extremely cost-effective option for device control, and one that’s also very easy to wire into an existing PCB or breadboard circuit design model. DIP switches also offer a quick and convenient way to physically see what settings are currently selected without having to power the system on first, and can drastically reduce the need for further expenditure on additional hardware to perform a wider range of output tasks.

Common applications for DIP switches in modern devices and circuits include:

- Configuration of a wide range of options on PC hardware and peripherals

- This includes motherboards, video cards, hard drives, modems, expansion modules and other accessories or auxiliary components

- DIP switches are still widely found on garage door opening mechanisms

- They’re commonly used in universal/multi-device remote controls to prevent electrical interference leading to accidental control of an unintended device

- In this case, the DIP switch will be used to set a different radio frequency for each pairing of transmitter and receiver

How DIP switches work

A standard surface-mountable DIP switch is sold as an array of basic two-terminal (on/off, or 1/0) electromechanical switches, assembled within a thermally stable plastic block housing. They’re often referred to generically as ‘jumpers’, although technically they’re actually an alternative to the traditional jumper - however, their overall function is very similar.

The 'dual in-line' portion of the acronym refers to the arrangement of the contact pins underneath the DIP switch, which plug directly onto the PCB or breadboard - these are arranged in two parallel rows on the underside of the DIP switch block, hence dual in-line. There will generally be twice the number of contact pins as switches on a given module.

DIP switches are useful wherever selecting a particular device function requires multiple switches to be toggled to achieve the right output mode. One of the most common applications for a DIP switch is on a computer motherboard, where various configuration settings can be accessed by toggling various switches to one position or the other.

A standard DIP switch might consist of 1, 2, 4, 7, 8, 10, 16 or even more toggle, rocker, slide or rotary switches mounted into a single small block. Although they’re simple components, the beauty of DIP switches is that having several toggles arranged in parallel means that each can be moved to 1/0 independently, potentially offering large numbers of different combinations to c

All the individual toggles in a single DIP switch array are electrically isolated from one another. When a toggle on a DIP switch is moved between its on/off positions, a flexible leaf spring underneath the switch responds to the movement of the slider or rocker, and bends slightly upward or downward in order to close or open a static contact below.orrespond with large numbers of possible device functions/outputs.

DIP switches are categorised for specific roles and applications by their safe operational current, voltage and power ratings. It’s important for users to observe and remain within the manufacturer’s given specifications for a particular DIP switch, otherwise problems such as self-welded switches and electrical arcing during switching can occur, risking performance instability or device damage.

How to use DIP switches

Types of DIP switches

There are numerous types of DIP switches available to buy from a range of suppliers and manufacturers on the current market, both in the UK and elsewhere. The most common varieties you’ll generally encounter with most sellers are rotary, slide or rocker DIP switches.

All types of DIP switch are widely deployed across various industries and applications today, including such uses as:

- PC expansion cards

- Arcade machines

- Automatic garage doors

- Measurement and test devices

- Industrial sectors and machinery controls

- Production and editing equipment

All the various DIP switch configurations perform essentially the same function as one another, but the form factor and exact method of toggling between on/off positions will be different for rotary, rocker and slider styles.

In this section, we’ll give a brief overview of some of these alternate DIP switch types.

Rotary DIP switches

A rotary DIP switch is one that the user turns through a circular range of motion - rather than toggles back and forth - either manually, or with a tool such as a screwdriver if that’s the way the switch was designed to actuate. Rotary coded DIP switches, just like rocker and slider varieties, are also intended to be mounted directly to a PCB where they will control the output behaviours of an electronic device.

A rotary DIP switch is one that the user turns through a circular range of motion - rather than toggles back and forth - either manually, or with a tool such as a screwdriver if that’s the way the switch was designed to actuate. Rotary coded DIP switches, just like rocker and slider varieties, are also intended to be mounted directly to a PCB where they will control the output behaviours of an electronic device.

They can be designed either to rotate continuously through 360 degrees, or to stop at preset positions as they turn. The amount of rotation the DIP switch shaft poasses through is what determines the binary or hexadecimal circuit code generated, and in turn the output signal sent to the device it’s wired in to.

While most rotary DIP switches can be used in much the same applications as any other type, they’re often seen as particularly handy options in scenarios where space on the PBC is especially limited, or where ease of adjustment for the user is considered paramount.

They’re available in waterproof, weather resistant and dustproof models from some sellers, and are widely used in precision measurement gauges, sound mixing and editing, test equipment, aerospace and military voice/data communications, and radio transmitters and receivers.

Slide/rocker/piano DIP switches

- Slide DIP switches, rocker DIP switches and piano DIP switches are really just variations on the second main type of DIP switch, namely the more traditional toggle switch. For all of these switch types, you can buy multiple variants including:

- Normally open (NO), meaning that their default position is to be disconnected from a circuit, and actuating the switch will complete it again

- Normally closed (NC), meaning that actuating the switch breaks contact with the circuit, rather than closing it

- A three stage switch, which will have three selectable positions (often On/Off/On), where the middle position will be default and pushing or sliding the switch to either side will actuate it

- Additionally, as is the case with the vast majority of all toggle switch types, DIP switches can also be found in various pole and throw configurations, including:

- single pole single throw (SPST) - this is the simplest type of switch you’ll encounter in most device types, in which a single toggle either connects or disconnects a single terminal to/from another one

- single pole double throw (SPDT) - a SPDT switch forces the operator to choose between connecting to either one of two terminals; as such, the switch will always be connected to one or the other, and the two terminals will never be connected together (although there may be a third position for ‘neither’ available, particularly when using slide switches)

- double pole double throw (DPDT) - essentially functions exactly like two separate SPDT switches, but where both sets of dual terminals are connected to a single actuator; the DPDT switch can control two separate circuits, but these are are always switched together when the toggle is moved

The number of individual switches on a single DIP switch module can vary from one or two through to 16 or more, and the number of positions advertised for a particular module will correspond to the number of individual switches it houses. Popular configurations or naming conventions you might come across in daily shopping include:

-

2 position dip switch

-

3 position dip switch

-

4 way dip switch

-

8-pin dip switch

-

8 way dip switch

-

10 position dip switch

-

10 dip switch

Summary

Despite the slight downturn in DIP switch use for some modern applications, where the increasingly cost-effective availability of software control panels and programmable on-board chips has impacted on their popularity to some extent, DIP switches are still seen as a very attractive option today in a wide range of industrial settings and circuit/device testing and design workflows.

Some of the many benefits of DIP switch arrays in certain circuits, design processes and device types include:

- There’s commonly an option for gold contacts on some higher-end DIP switch models, offering greatly enhanced reliability and efficiency

- They work as a handy replacement for older jumpers

- Units vary from 1 through to 32 poles, offering huge potential for flexibility and functionality

- Longer poles on some models can cut down loading times in intensive production environments

- DIP switches can be modified by cutting their poles to required level for PCB/breadboard mounting

- They’re available in both PCB surface mount and through-hole mounting configurations

- They typically display good service temperature ranges for use in nearly all environments

- Some models are designed to offer shock and vibration resistance

- They’re inexpensive and very easy to work with

If you’d like any further information or advice on buying and installing DIP switches or any other type of circuit control components and accessories, please feel free to contact a member of our expert support team by phone or email.

Product spotlights

Click the links below to shop the most popular switch position types: