|

Related technologies

New value for control panels

Control panels:

The heart of manufacturing sites

If panel design, panel manufacturing processes and human interaction with panels can be innovated by way of new products, wiring techniques and technologies, then control panel manufacturing becomes simpler and makes a huge leap forward in terms of efficiency.

Starting with our shared Value Design for Panel concept for control panel product specification, Omron looks to offer control panel evolution and process innovation for the customers.

| Panels | Process | People |

Panels

Space saving

By adding devices in the newly available space, you can both mount more devices in the same size control panel to increase control panel functionality, or get a smaller final panel design.

Process

Swift customisation

Devices with unified specifications allow to easily exchange modules customising panels for each customer.

Side-by-side mounting is possible due to reduced power consumption (therefore generating less heat) for each model at an ambient temperature of 55°C.

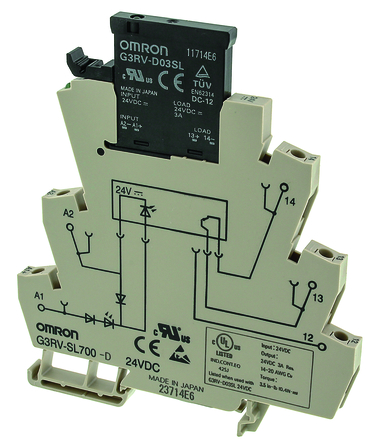

Brand: RS Pro

People

Easy wiring

Terminal blocks with push-in plus technology have been developed by Omron to provide easy wire insertion and firm wire holding, therefore reducing the time and work involved in wiring.

Terminal block cable entries, independently developed with push-in plus technology, are all face forward for easy wire insertion.